This case study highlights how IFC Inflow delivered a customised hose support solution for an industrial chemical manufacturer. By addressing a challenging site layout, we improved safety, reduced manual handling, and increased efficiency in tanker loading operations.

The Challenge

An industrial chemical manufacturer in Essex asked IFC Inflow to improve safety and efficiency during tanker loading and unloading. Their main goal was to reduce manual handling and minimise trip hazards, particularly with the heavy hoses used in daily operations.

The new loading station created a specific challenge. A narrow bund wall, only 300mm wide, made it difficult to install a standard hose support system. The hose support standpost had to be strong enough to hold the weight of a 4m hose while staying out of the way of incoming traffic.

The Hose Support Solution

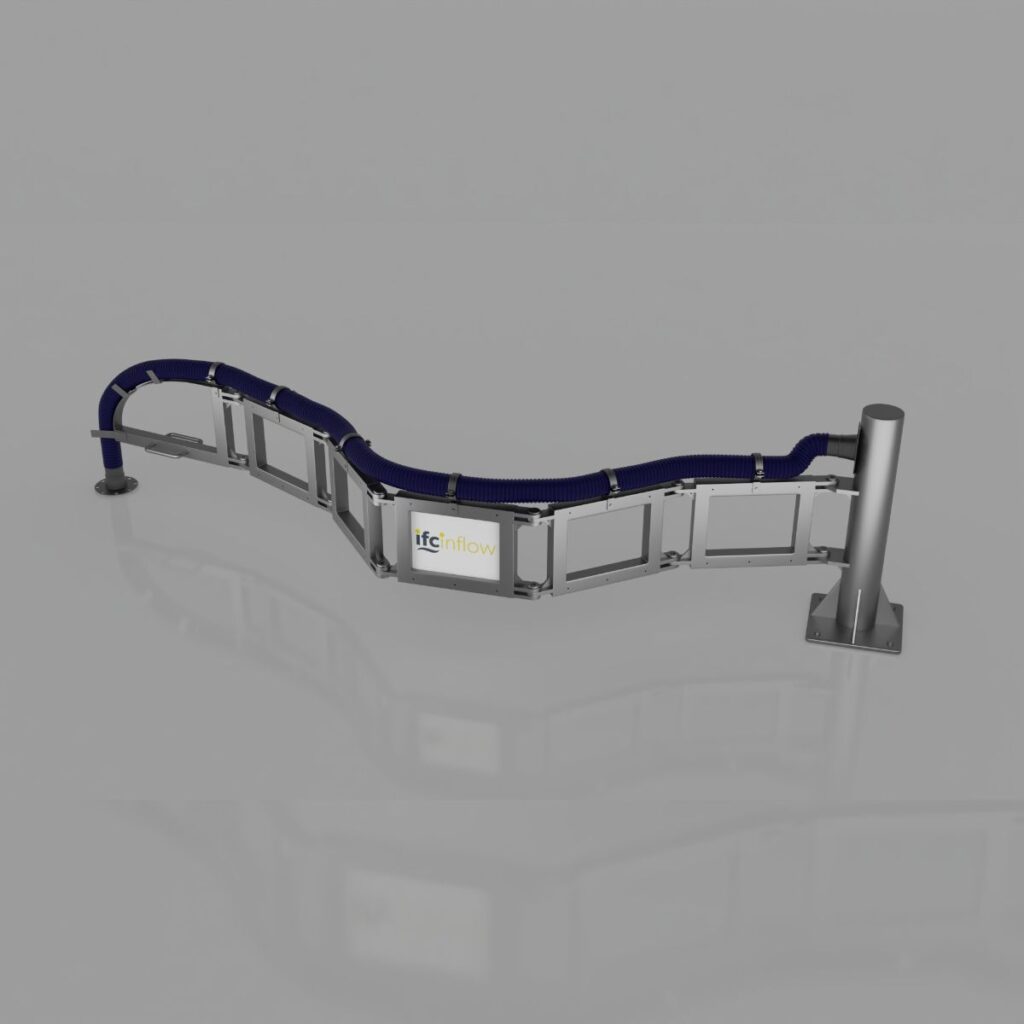

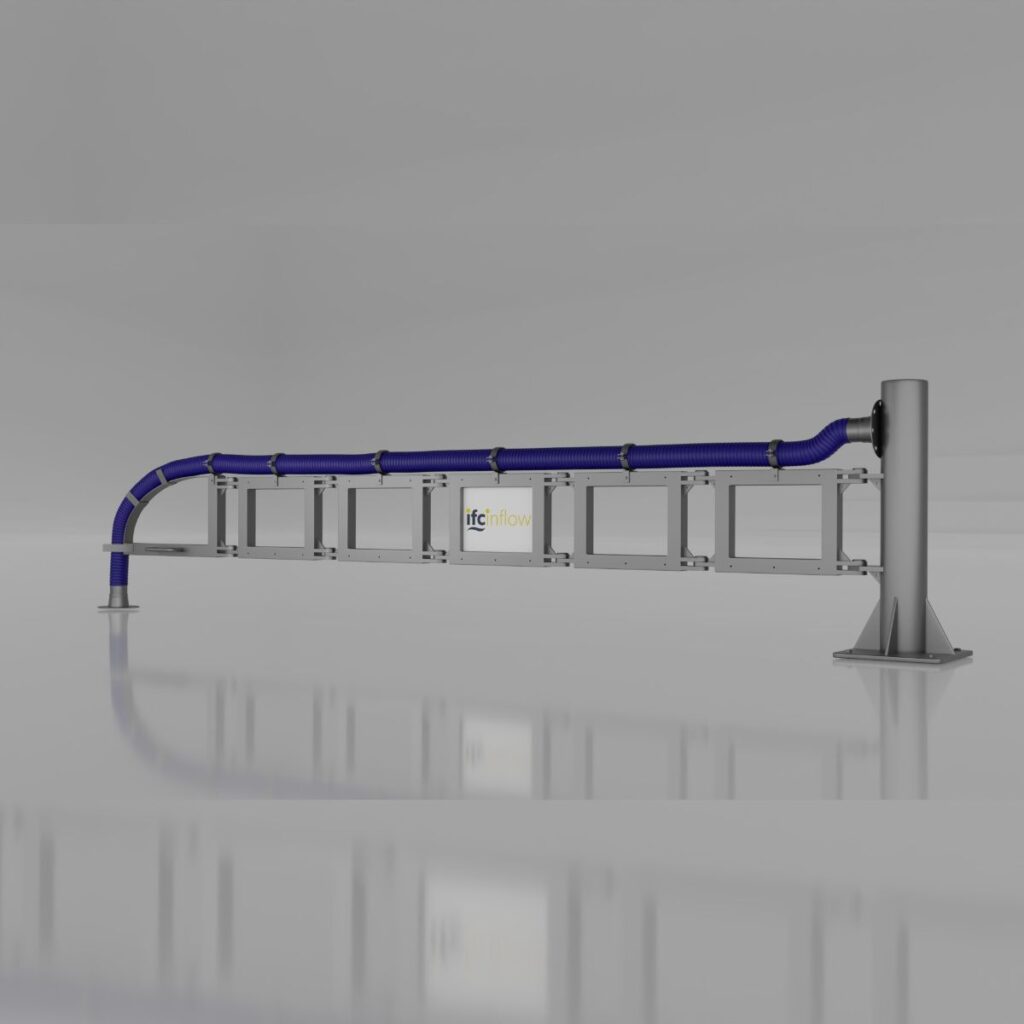

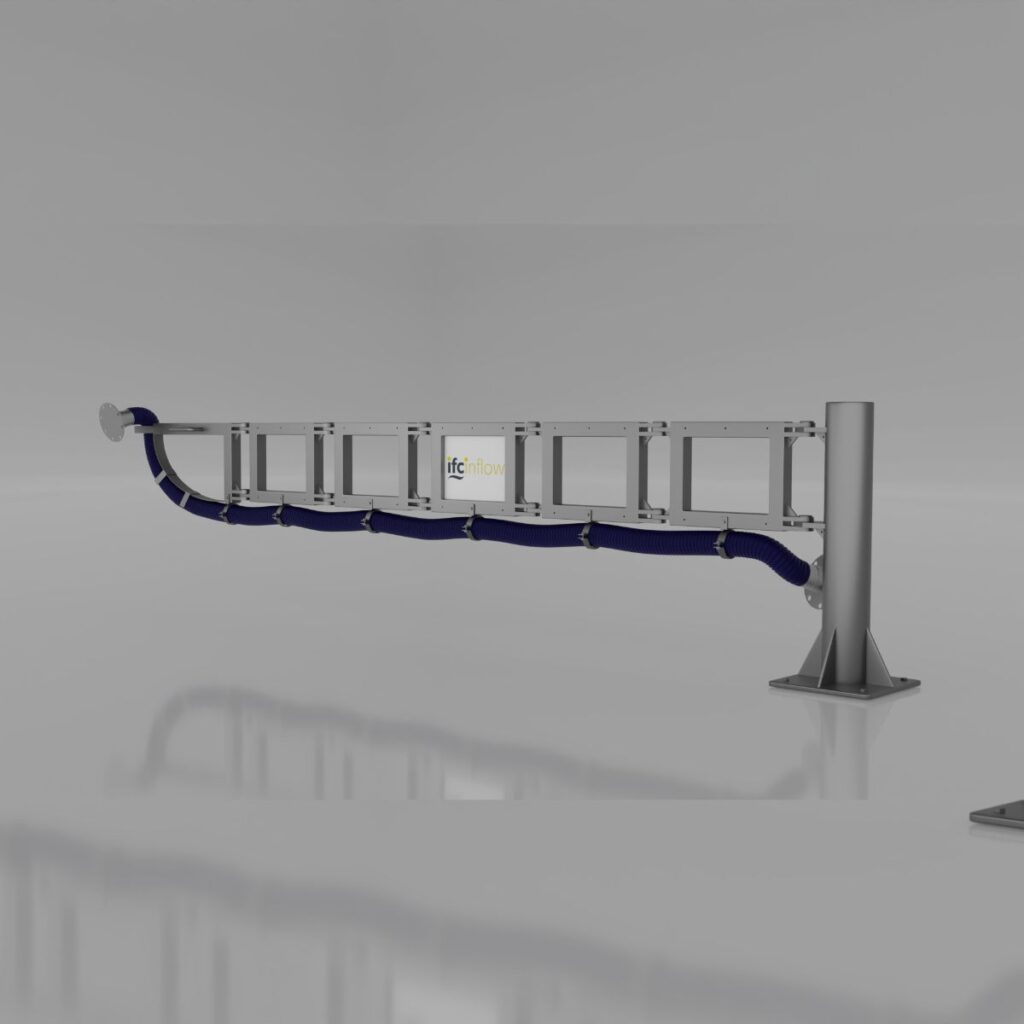

Following a site visit, IFC Inflow recommended a customised hose support solution. We designed a 4m support arm with a shorter standpost to fit the narrow space. The system offered enough strength to carry the weight of the hose while preventing it from dragging on the ground. This reduced wear and tear and extended the hose lifespan.

The new design also removed the need for manual handling. Operators could simply swing the hose support into position with ease, making the process quicker and safer.

The Outcome

The system was delivered in flatpack form, and the client assembled it themselves. Within one day, the hose support solution was fully operational.

The benefits were clear straight away. The new hose support system improved safety by keeping hoses off the ground and reducing slip and trip hazards. It also made the loading and unloading process more efficient, with a single operator now able to complete the task without heavy lifting.

Features and Benefits of the Hose Support Solution

- Customisable design: Tailored to fit unique site requirements such as narrow bund walls.

- Improved safety: Eliminates manual handling and reduces slip and trip risks.

- Extended hose lifespan: Prevents dragging and wear, helping hoses last longer.

- Efficiency gains: Streamlines loading and unloading by keeping hoses easy to access.

- Quick assembly: Delivered in flatpack form and assembled on-site, reducing downtime.

Project Summary

This case study shows how IFC Inflow delivered a hose support solution that improved safety, reduced risks, and increased efficiency for a chemical manufacturer. With decades of industry experience, we continue to design tailored systems that solve site-specific challenges and deliver reliable results in tanker loading operations. Check out the full details of the Hose Support System here. If you’d like to discuss a project then you can contact us here.