Multi Level Fall Prevention System Increases Safety At Chemical Company

Installation of a MultiLev – Multi Level Platform (MLP) Client: Global Chemical CompanyIndustry: ChemicalsSite: UK Overview A global chemical company with worldwide manufacturing and distribution plants including sites in the UK and Europe wanted to speed up their tanker loading operations, whilst increasing the level of safety for their operators when accessing and working on […]

Irish Chemical Manufacturer Increases Site Capacity With New Tanker Loading Bay

IFC Inflow was recently called to the site of an Irish Chemical Manufacturer and Distributor in Shannon, Republic of Ireland. The customer was installing a new chemical tanker loading bay and wanted our help to make sure it was as safe as possible for workers accessing the tops of tankers to carry out loading operations. […]

Sliding Folding Stairs Provide Safe Chemical Tanker Access To Waste Treatment Company

We were approached by waste treatment and transfer station, BIP Environmental. BIP handle multiple hazardous and non-hazardous products used by their customers. Tankers visiting their site require regular and thorough cleaning in order to avoid contamination when loading in new chemicals. Workers are required to get on top of the tankers when carrying out cleaning […]

Flexible Access Solution For Paints & Coatings Tanker

We recently completed a job for IG Doors, a door manufacturer supplying a range of markets with innovative and secure entry solutions. The company would have tankers on site, delivering paint/ chemicals to coat their doors, every few months or so. Their loading/ unloading process involved manoeuvring their hose to the top of the tankers […]

Safe And Flexible ISO Tanker Access For Chemical Company

In 2023, IFC Inflow were called to the site of a Chemical company in Southampton that were concerned about the safety of their staff loading their ISO tankers. The nature of the site meant the company had various tankers being loaded and unloaded in different locations, with operators being required to climb onto the backs […]

Major Chemical Company Seek Specialist Loading Arm

We recently completed a project for a large-scale Chemical Manufacturer, helping streamline their loading operations. They were looking at ways to reduce manual handling on site and reduce risks of leaks and spillages. We were called to their site where they were loading and unloading several ISO tankers daily with a butadiene liquid. The existing […]

International Chemical Company Reimagines Loading System

IFC Inflow were invited to a composite and coating company in Mitcham to help improve the safety and efficiency of their loading operations. While the company were using a bottom loading system to load their tankers, avoiding any risk of fall from height related accidents, the heavy hoses were posing a risk to employee safety. […]

Global Chemical Manufacturer Approach IFC For Top Loading Upgrade

Site programme for chemical top loading plant upgrade Overview A leading global chemical manufacturer based in the North East of England approached IFC to assist them with upgrading their old chemical loading facility. The company specialises in the production of acrylics including the industry-leading brand Perspex. In a site upgrade programme at their plant, they required […]

Total Tanker Safety Cage For Global Chemical Manufacturer

Installation of pneumatically powered Total Tanker Safety Cage Client: Major chemical manufacturing companyIndustry: ChemicalsSite: West Midlands, UK Overview: A pneumatically powered Total Tanker Safety Cage was required for a global chemical manufacturer in the UK. The client is a leading global manufacturer and developer of specialty resins, chemical intermediates, and solutions. These are critical to the performance and quality […]

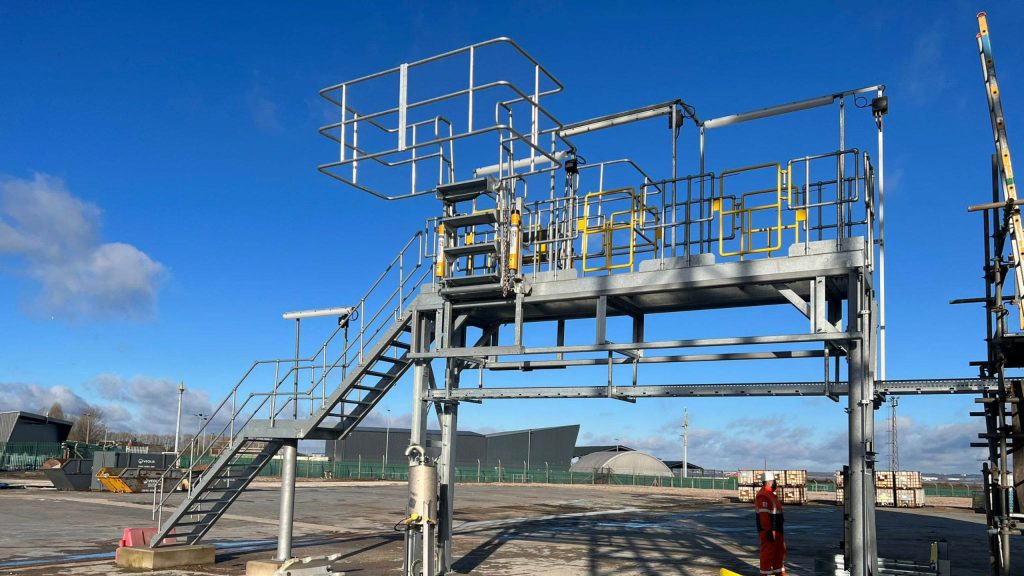

Safe Tanker Access Gantry & Fall Prevention Safety Cages

Meeting health & safety working at height regulations Client: Omya UKIndustry: Minerals and ChemicalsSite: Aggregates plant in Derbyshire Overview Safe tanker access gantry was required by Omya UK to adhere to health and safety working at height regulations. Omya UK is a leading supplier of white minerals and chemicals – both in the UK and around the world as part of […]